At L’Oréal, every day, we strive to reach industrial and operational excellence. Quality is at the center of everything we undertake. Our goal is to always provide you with cosmetic products that correspond to the highest quality standards.

Quality at the heart from design to sourcing of raw materials and packaging, manufacturing and distribution

-

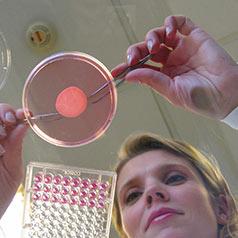

Raw materials:

To manufacture a quality cosmetic product, a meticulous selection of high-calibre raw materials and packaging is essential. That is why we take time to select the best raw materials and packaging for our products, making sure they are all of the finest quality and in line with your expectations.

-

Suppliers:

To ensure raw materials are of impeccable quality for our consumers, we strive to work with the best suppliers. To identify them, we perform exhaustive quality audits which enable us to work only with suppliers that we know and trust.

Our close relationships with suppliers give us control over the reliability and traceability of raw materials and packaging, and mean that we know the history of products we place on the market.

It also enables us to ensure that the quality of the raw materials and packaging is both fitting and in line with the latest regulatory standards. -

Packaging:

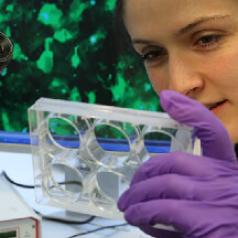

We also strictly control the quality of the final packaging, which plays an active role in the beauty experience. This involves multiple laboratory tests.

To ensure the finest possible product quality, all raw materials and packaging are checked one more time when they enter the plant prior to manufacturing. -

Finished products:

Our teams make sure that the formula is compatible with its packaging. Taking the example of a mascara, we do not only check the product itself but also the brush that goes with it. We test for instance the friction of the brush against its case.

-

Resistance:

We run tests at our plants and distribution locations prior to delivery to make sure that products have stood up to possible shocks and are still intact.

At each step, we are demanding and our quality requirements apply at every level: in each of our subsidiaries, for each of our brands and every product we make.

Our staff follows strict in-house standards that can exceed the regulatory requirements. We aim at making sure our products are of the highest possible quality at every stage of production. Over the course of the production cycle, every product is subject to about 100 quality controls.

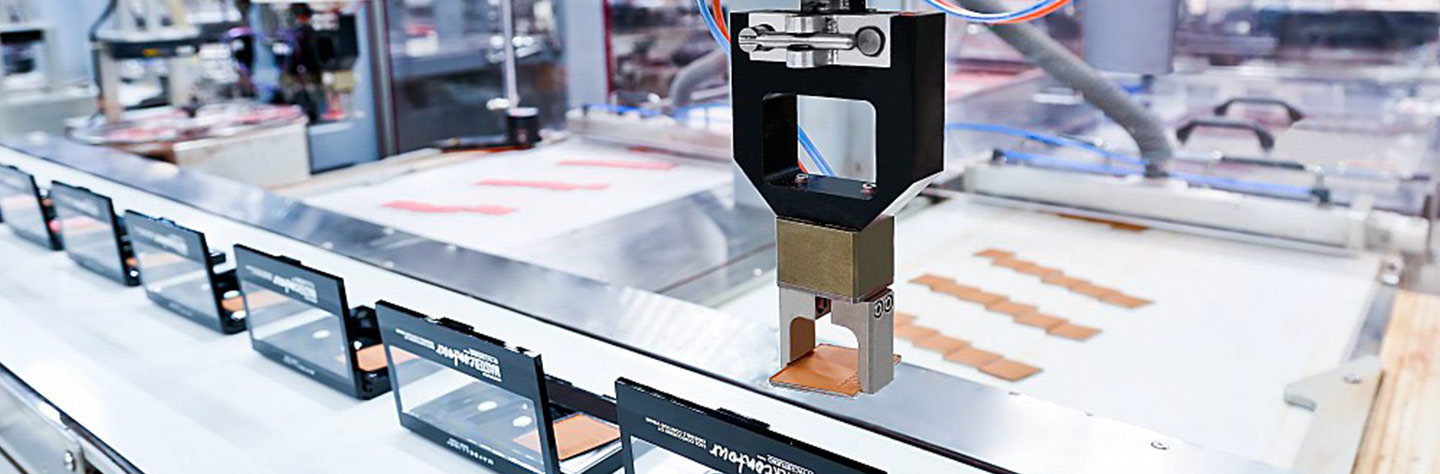

Harnessing technological advances to enhance quality

To ensure the best product quality, we stay at the forefront in terms of technology. This is why our plants integrate an ever-increasing number of ultra-modern technologies from the 4.0 Industry.

A prime example is the Lassigny plant in France, which in recent years has been using cobots - smart, collaborative robots - that allow employees to save valuable time, leaving them free to focus on quality control and improving their know-how.